Material

Indexing plunger:

Threaded sleeve stainless steel 1.4305.

Indexing pin stainless steel 1.4034.

Actuating element stainless steel 1.4305.

Mushroom grip thermoplastic.

Plastic cap thermoplastic.

Wire cable stainless steel 1.4401.

Traction sleeve steel wire with plastic sleeving inside and outside.

End sleeves, setscrews and screw nipples brass.

Version

Indexing pin, hardened, ground and bright.

Bowden cable casing, black.

Mushroom grip, thermoplastic dark grey.

Bowden cable casing, black.

Mushroom grip, thermoplastic dark grey.

Show more

Show less

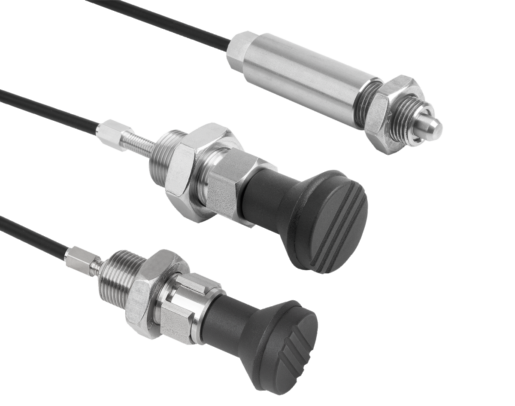

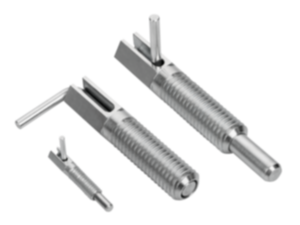

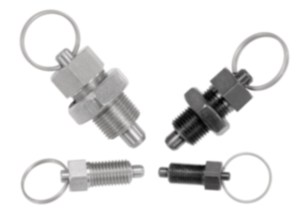

Indexing plunger, stainless steel with remote operation

from

33,93 €

plus sales tax

plus shipping costs

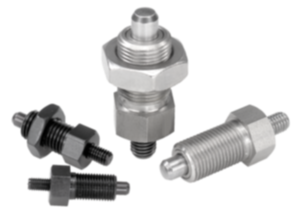

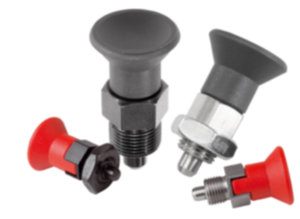

Actuating elements for indexing plungers with remote actuation, with plastic mushroom grip and locknut

from

23,81 €

plus sales tax

plus shipping costs

Actuating elements for indexing plungers with remote actuation, with plastic mushroom grip, locking slot and locknut

from

34,13 €

plus sales tax

plus shipping costs

Description

Product description

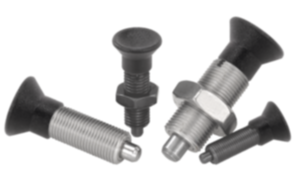

Indexing plungers are used where any change in locking position due to lateral forces should be prevented.

Some examples of this are for length, height and position indexing in machine, furniture and special vehicle construction.

Indexing plungers with remote actuation are used where inaccessible assembly spaces are making it difficult to operate, or where remote actuation is required for ergonomic or safety reasons.

The indexing plunger is connected to the operator side by a Bowden cable. The combination of indexing plunger and actuating element forms a complete system which can be used for many types of application. Form D should be used for applications where the indexing pin should remain disengaged for an extended period and be prevented from springing back.

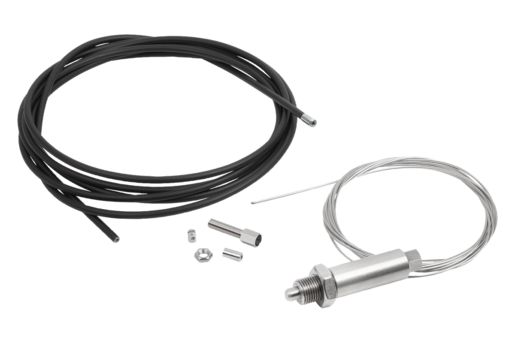

As an alternative to the actuating element, the supplied screw nipple (Ø5 x 7 mm) can be used to integrate an individual actuating element into the system.

The Bowden cable is available in various lengths.

To ensure an exact fit in the application concerned, the Bowden cable can be shortened as required during installation.

Corrosion protection is achieved by selecting a suitable material and surface treatment. The wire cable or cable sheath can be easily replaced if required.

Some examples of this are for length, height and position indexing in machine, furniture and special vehicle construction.

Indexing plungers with remote actuation are used where inaccessible assembly spaces are making it difficult to operate, or where remote actuation is required for ergonomic or safety reasons.

The indexing plunger is connected to the operator side by a Bowden cable. The combination of indexing plunger and actuating element forms a complete system which can be used for many types of application. Form D should be used for applications where the indexing pin should remain disengaged for an extended period and be prevented from springing back.

As an alternative to the actuating element, the supplied screw nipple (Ø5 x 7 mm) can be used to integrate an individual actuating element into the system.

The Bowden cable is available in various lengths.

To ensure an exact fit in the application concerned, the Bowden cable can be shortened as required during installation.

Corrosion protection is achieved by selecting a suitable material and surface treatment. The wire cable or cable sheath can be easily replaced if required.

Material

Indexing plunger:

Threaded sleeve stainless steel 1.4305.

Indexing pin stainless steel 1.4034.

Actuating element stainless steel 1.4305.

Mushroom grip thermoplastic.

Plastic cap thermoplastic.

Wire cable stainless steel 1.4401.

Traction sleeve steel wire with plastic sleeving inside and outside.

End sleeves, setscrews and screw nipples brass.

Version

Indexing pin, hardened, ground and bright.

Bowden cable casing, black.

Mushroom grip, thermoplastic dark grey.

Bowden cable casing, black.

Mushroom grip, thermoplastic dark grey.

Note for ordering

Indexing plungers with remote actuation and actuating element must be ordered separately.

Note

When installing the Bowden cables, the following points should be noted:

The length of the free end of the cable can change due to the layout angle, bending radius and load factors. So, after laying the Bowden cable, the length of the counter-bearing (casing) must be adjusted using the adjusting screw supplied. The adjusting screw is also used to set the pretension in the Bowden cable system.

When laying the cable, particular care must be taken to ensure that the bending radius is not below the minimum value, which in this case is R = 65 mm. A radius which is too narrow can lead to increased wear and higher friction.

Also avoid letting the bending radius briefly go below the minimum value when installing, as this can cause damage to the casing. Also, the casing is designed only to support pressure forces. If pulled too sharply, the inner coil will be stretched and permanently damaged.

The length of the free end of the cable can change due to the layout angle, bending radius and load factors. So, after laying the Bowden cable, the length of the counter-bearing (casing) must be adjusted using the adjusting screw supplied. The adjusting screw is also used to set the pretension in the Bowden cable system.

When laying the cable, particular care must be taken to ensure that the bending radius is not below the minimum value, which in this case is R = 65 mm. A radius which is too narrow can lead to increased wear and higher friction.

Also avoid letting the bending radius briefly go below the minimum value when installing, as this can cause damage to the casing. Also, the casing is designed only to support pressure forces. If pulled too sharply, the inner coil will be stretched and permanently damaged.

Scope of delivery

Indexing plunger with remote actuation:

Indexing plunger with preassembled cable, casing, end sleeve, adjusting screw M6 x 34 mm and screw nipple Ø5 x 7 mm.

Actuating element:

Actuating element with plastic cover.

Indexing plunger with preassembled cable, casing, end sleeve, adjusting screw M6 x 34 mm and screw nipple Ø5 x 7 mm.

Actuating element:

Actuating element with plastic cover.

On request

Special versions.

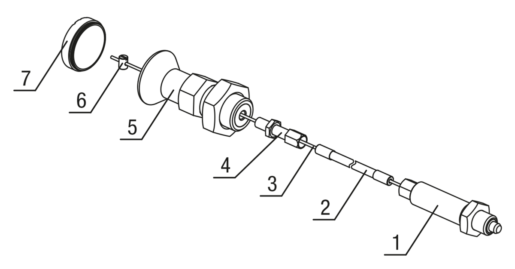

Drawing reference

1) Indexing plunger

2) Bowden cable casing

3) Bowden cable

4) Adjusting screw

5) Actuating element

6) Screw nipple

7) Cover

Form B: non-lockout type, with locknut

Form D: lockout type, with locknut

2) Bowden cable casing

3) Bowden cable

4) Adjusting screw

5) Actuating element

6) Screw nipple

7) Cover

Form B: non-lockout type, with locknut

Form D: lockout type, with locknut

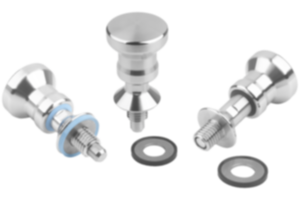

Accessory

Hex nuts K0700.

Mounting brackets K0638.

Spacer rings K0665.

Positioning bushes K1290.

Actuating elements K1502.12420.

Bowden cable K2116

Wire cables K2023.

Tension sleeves K2024.

End sleeves K2025.

Setscrews K2026.

Screw nipples K2027.

Mounting brackets K0638.

Spacer rings K0665.

Positioning bushes K1290.

Actuating elements K1502.12420.

Bowden cable K2116

Wire cables K2023.

Tension sleeves K2024.

End sleeves K2025.

Setscrews K2026.

Screw nipples K2027.