Material

Housing plastic.

Shaft stainless steel.

Connector thread brass.

Earthing terminal metal.

Shaft stainless steel.

Connector thread brass.

Earthing terminal metal.

Version

Nickel-plated brass.

1x M8 connector (A coded), 4-pole, 1x pin.

1x M8 connector (A coded), 4-pole, 1x pin.

Show more

Show less

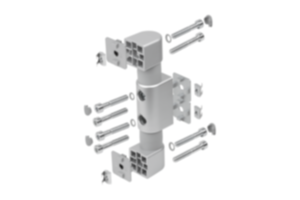

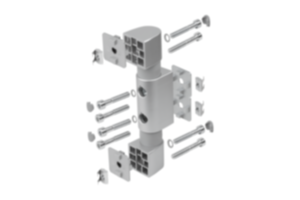

Position indicator, plastic, electronic IO link interface, Form A, with hollow shaft

from

€462.85

plus sales tax

plus shipping costs

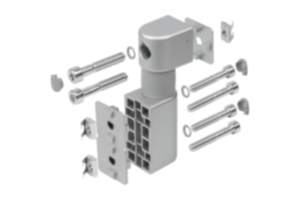

Position indicator, plastic, electronic IO link interface, Form B, with magnetic sensing

from

€394.99

plus sales tax

plus shipping costs

Description

Material

Housing plastic.

Shaft stainless steel.

Connector thread brass.

Earthing terminal metal.

Shaft stainless steel.

Connector thread brass.

Earthing terminal metal.

Version

Nickel-plated brass.

1x M8 connector (A coded), 4-pole, 1x pin.

1x M8 connector (A coded), 4-pole, 1x pin.

Note

The IO link-enabled position indicators are used to check format adjustments, in order to effectively reduce set-up times and increase machine efficiency.

The two-line LCD display can display both the setpoint value and the actual value.

Two LEDs give the user visual signals indicating whether the setpoint and actual values match (LEDs lit green) or do not match (LEDs lit red). The LEDs also indicate to the user which direction of adjustment to apply in order to reach the desired position.

Position indicators K1657.1530 and K1657.1650 are linked to the application by a shaft. The position of the application is determined by a robust sensor system which uses magnetic scanning.

Position indicators K1657.1531 and K1657.1651 are mounted directly in the application. The position is determined by a magnetic sensor (K1658) and a magnetic tape (K1663). Suitable only for linear length measurement.

The two-line LCD display can display both the setpoint value and the actual value.

Two LEDs give the user visual signals indicating whether the setpoint and actual values match (LEDs lit green) or do not match (LEDs lit red). The LEDs also indicate to the user which direction of adjustment to apply in order to reach the desired position.

Position indicators K1657.1530 and K1657.1650 are linked to the application by a shaft. The position of the application is determined by a robust sensor system which uses magnetic scanning.

Position indicators K1657.1531 and K1657.1651 are mounted directly in the application. The position is determined by a magnetic sensor (K1658) and a magnetic tape (K1663). Suitable only for linear length measurement.

Technical Data

Position indicators K1657.1530 and K1657.1650:

Rotation speed: ≤500 rpm

Operating voltage: 24 V DC ±20 %

Current consumption: ~30 mA

Battery life: ~5 years

Resolution: 880 increments/rotation

Measurement range: ≤11914 rotations

Ambient temperature: 0 °C to +60 °C

Storage temperature: -20 °C to +80°C

Position indicators K1657.1531 and K1657.1651:

Operating voltage: 24 V DC ±20 %

Current consumption: ~30 mA

Battery life: ~5 years

Resolution: 0.01 mm (with magnetic sensor K1658)

System accuracy: ±35 µm (with magnetic sensor K1658)

Measurement range: ±655 m (with magnetic sensor K1658)

Ambient temperature: 0 °C to +60 °C

Storage temperature: -20 °C to +80°C

Rotation speed: ≤500 rpm

Operating voltage: 24 V DC ±20 %

Current consumption: ~30 mA

Battery life: ~5 years

Resolution: 880 increments/rotation

Measurement range: ≤11914 rotations

Ambient temperature: 0 °C to +60 °C

Storage temperature: -20 °C to +80°C

Position indicators K1657.1531 and K1657.1651:

Operating voltage: 24 V DC ±20 %

Current consumption: ~30 mA

Battery life: ~5 years

Resolution: 0.01 mm (with magnetic sensor K1658)

System accuracy: ±35 µm (with magnetic sensor K1658)

Measurement range: ±655 m (with magnetic sensor K1658)

Ambient temperature: 0 °C to +60 °C

Storage temperature: -20 °C to +80°C

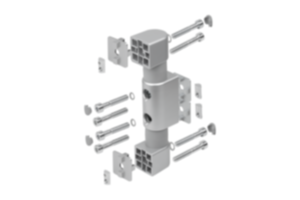

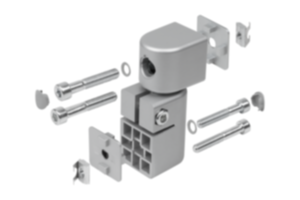

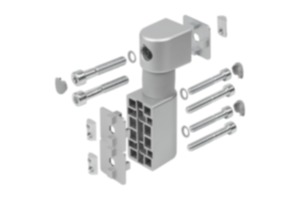

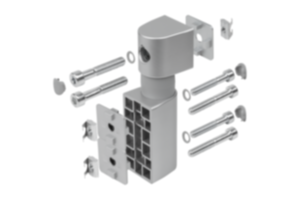

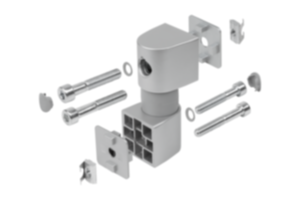

Scope of delivery

Position indicators

Assembly instructions

Assembly instructions

On request

Certificate of conformity.

Attention

These position indicators can be integrated only with a IO link communication system.

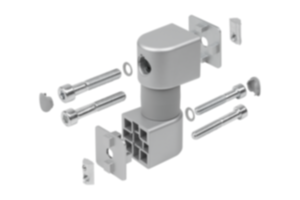

Drawing reference

1) Torque support

2) Grub screw M3 (2x 120°)

3) Min. space required to change battery without disassembling.

4) 2x M5/7 deep

5) Contact area

6) Earthing terminal for flat connector 6.3 or cable lug

7) IO link M8 connector (pin contact) metal connection thread

8) Sensor

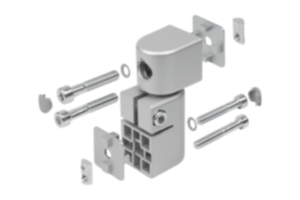

2) Grub screw M3 (2x 120°)

3) Min. space required to change battery without disassembling.

4) 2x M5/7 deep

5) Contact area

6) Earthing terminal for flat connector 6.3 or cable lug

7) IO link M8 connector (pin contact) metal connection thread

8) Sensor

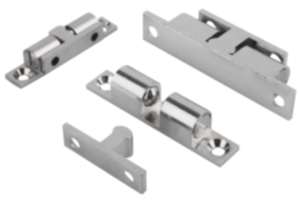

Accessory

Position indicators K1657.1530 and K1657.1650:

Reducing bush K0412.20**.

Position indicators K1657.1531 and K1657.1651:

Magnetic sensor K1658.

Magnetic tape K1663.

Reducing bush K0412.20**.

Position indicators K1657.1531 and K1657.1651:

Magnetic sensor K1658.

Magnetic tape K1663.