Material

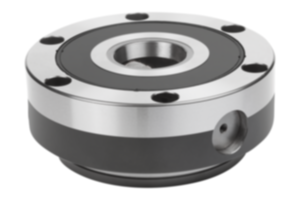

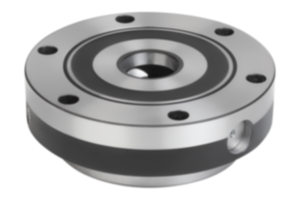

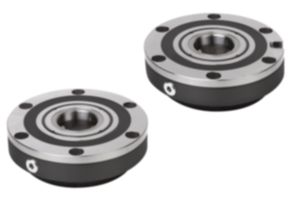

Clamping module high-carbon steel.

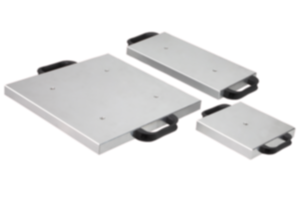

Baseplate steel 1.1730.

Baseplate steel 1.1730.

Version

Clamping module contact faces hardened and ground.

Baseplate ground on both sides.

Baseplate ground on both sides.

Show more

Show less

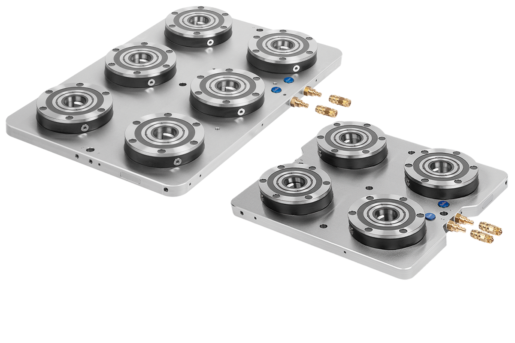

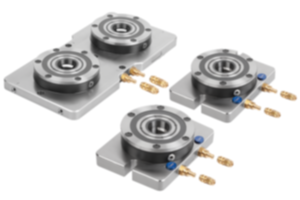

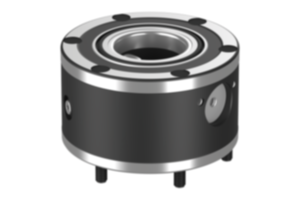

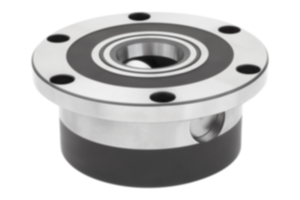

UNILOCK clamping station, 4x

from

On request

plus sales tax

plus shipping costs

UNILOCK clamping station, 6x

from

On request

plus sales tax

plus shipping costs

Description

Material

Clamping module high-carbon steel.

Baseplate steel 1.1730.

Baseplate steel 1.1730.

Version

Clamping module contact faces hardened and ground.

Baseplate ground on both sides.

Baseplate ground on both sides.

Note

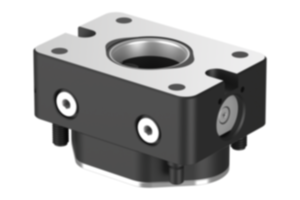

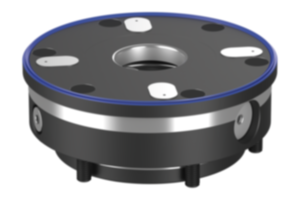

Pre-assembled multi-clamping stations with integrated UNILOCK ERGO 138 clamping modules. The clamping stations are attached to the machine table by means of clamping brackets or by bolts.

Standard hole patterns on the back for fastening are pre-centred.

The clamping stations can be aligned using the 14H7 reference holes.

The clamping modules are actuated using a central pneumatic connection.

The high clamping forces are generated by the integrated spring package. (the unit clamps in while not under pressure).

Clamping is released pneumatically.

The following clamping forces are possible with the UNILOCK clamping pin in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N/module

- Clamping force (M12) 50,000 N/module

- Clamping force (M16) 75,000 N/module

Clamping force with DIN EN ISO 4762 -12.9 cap screws

Clamping pins may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

Standard hole patterns on the back for fastening are pre-centred.

The clamping stations can be aligned using the 14H7 reference holes.

The clamping modules are actuated using a central pneumatic connection.

The high clamping forces are generated by the integrated spring package. (the unit clamps in while not under pressure).

Clamping is released pneumatically.

The following clamping forces are possible with the UNILOCK clamping pin in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N/module

- Clamping force (M12) 50,000 N/module

- Clamping force (M16) 75,000 N/module

Clamping force with DIN EN ISO 4762 -12.9 cap screws

Clamping pins may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

Technical Data

- Retraction force with turbo from 18 kN/module

- Opening pressure: 6 bar, lubricated air.

- Turbo pressure: 6 bar.

- Air connection: G1/4

- Repeat accuracy ≤ 0.005 mm

- Reference holes 14H7 to align the clamping plate.

- Opening pressure: 6 bar, lubricated air.

- Turbo pressure: 6 bar.

- Air connection: G1/4

- Repeat accuracy ≤ 0.005 mm

- Reference holes 14H7 to align the clamping plate.

On request

Clamping station in special dimensions.

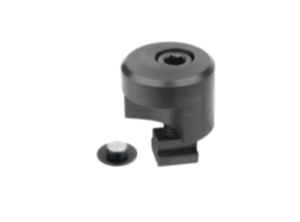

Accessory

UNILOCK clamping bracket for UNILOCK clamping station K1869.